Specialist installer of resin bound systems

Our highly experienced team have over 20 years of experience working with resin bound systems. Resin offers a stylish and practical ways to completely transform any surface.

Resin bound is a specialist resin and aggregate surface, a natural choice for large pedestrianised areas, access roads, tree pits and vehicular traffic. It’s slip resistant, durable, porous and low maintenance. Available in a range of natural colours and hybrid recycled systems, our quality resin bound surfaces are Sustainable Drainage System (SuDS) compliant and can be laid on asphalt, flexipath, cementitious and ‘no-dig’ systems.

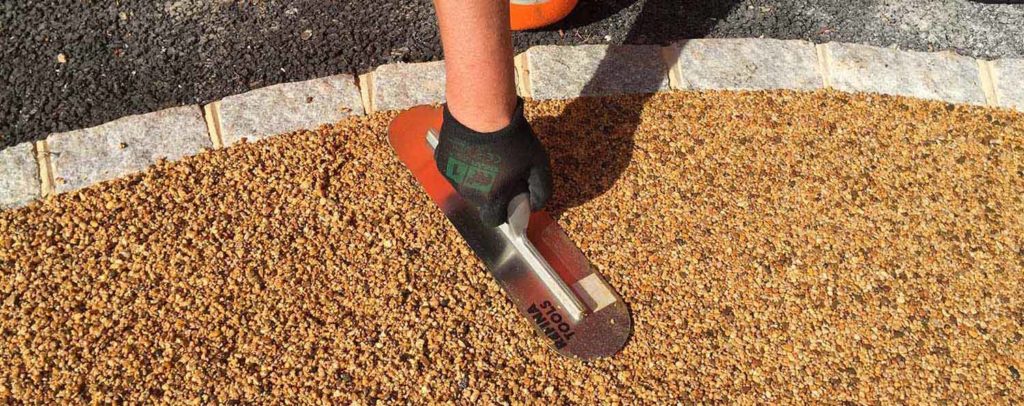

A Resin Bound surface is mixed on site and cold applied, using a high-quality clear resin binder to coat the aggregate particles prior to laying. Unlike resin-bonded surfacing, where a thin layer of resin is applied to the surface and then the aggregate scattered on top (which can then become loose over time and is impermeable), resin and aggregates are thoroughly mixed together prior to laying, ensuring that the aggregate is completely coated and so providing a totally bound surface. As a result, a resin-bound surface is more durable and requires less maintenance – it needs to be swept or power washed at least twice a year, to avoid the build up of detritus and prevent the growth of moss or algae.

Ready to speak to us?

Contact us today on 01628 529 421

Our experts

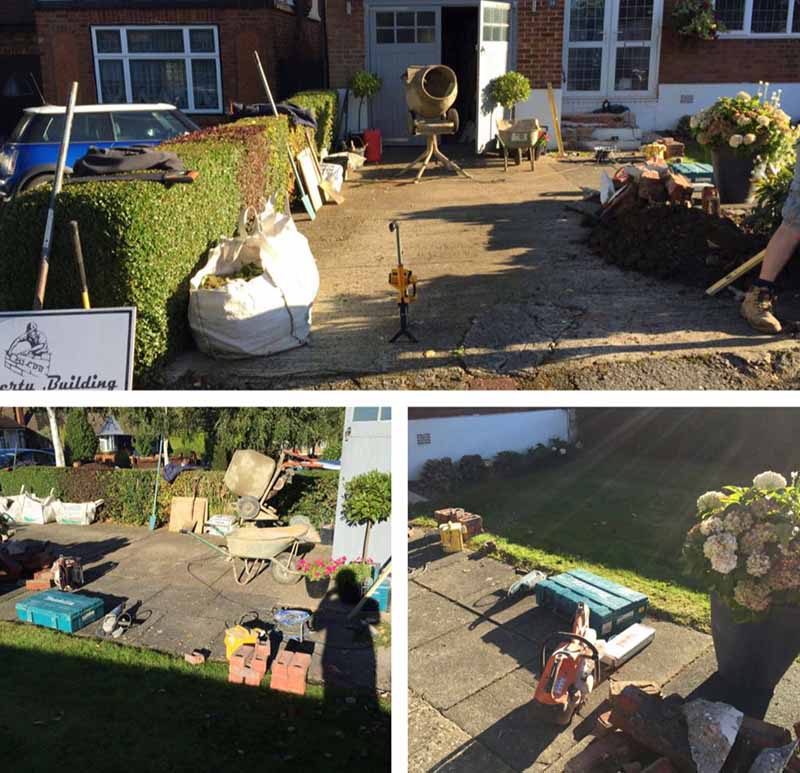

We resource our contracts with fully trained and certified in house labour and plant, meeting the highest expectations and standards of the industry. We employ our own health and safety management to monitor and advise on Health, Safety and Environmental issues whilst all levels of management are responsible for the health, safety and wellbeing of our employees, customers and members of the public on our sites.

Our friendly and approachable contracts staff will be on site to supervise all stages of the contract, from initial site clearance to lining, lighting and security barriers. We will deliver the customer the full package in a timely, efficient manner, on time and within budget.

If you have a project and require our expert assistance contact Spadeoak today on 01628 529 421 or email sales@spadeoak.co.uk